Magtrol

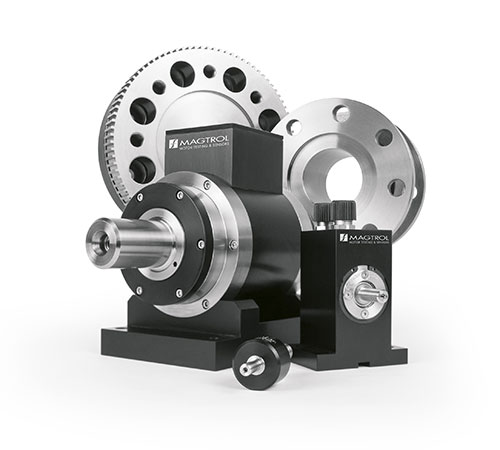

Magtrol Motor Test Equipment

Magtrol offers three types of Dynamometers, each with a different braking system to absorb load: Hysteresis, Eddy-current and Powder. Magtrol’s dynamometers, electronics and software are used for testing all types of electric and pneumatic motors, gas engines and gearheads, as well as servo drives and inverters.

With over 50 dynamometers to choose from, and the availability of Customized Motor Test Systems (CMTS), virtually every motor testing requirement can be met.

Magtrol Torque Transducers

Provides excellent long-term stability and reliability using a highly accurate non-contact measuring technique. Special units made to customer requirements are available.

Magtrol Brakes and Clutches

Pure Hysteresis Brakes produce torque strictly through a magnetic air gap without the use of magnetic particles or friction components.

Like the Hysteresis Brake, the Magtrol Hysteresis Clutch develops torque strictly through a magnetic air-gap, ensuring an absolutely smooth transmission of torque from the drive unit to the driven element.

Magtrol Load-Force-Weight Systems

Highly reliable systems to measure and monitor load, force and weight, commonly used to provide safety, control and overload protection. Typical applications requiring Load-Force-

Weight Systems include cranes, ski lifts, harbor installations, oil drilling (on and off shore), hoists, winches and other heavy lifting equipment.

Magtrol Displacement Transducers

Magtrol’s line of Displacement Transducers provide contactless measurement of absolute piston position in hydraulic and pneumatic cylinders and other applications. Their robust construction, large insensitivity to shocks and very long life (due to no moving parts and therefore no wear of components) make them both cost effective and very reliable.