Compression Seal & Fiber Optic Fittings

Browse our catalog of compression seal and fiber optic fittings that offer secure connections between cables. Compression seal fittings, also known as sealing glands, are used to seal elements that pass through either an environmental or pressure boundary. To create the seal, compression seal fittings use mechanical components and an axial force to compress a soft sealant that is within a body. This allows for ease of installation, adjustment, and replacement of the elements. For fiber optic fittings, connectors are spring-loaded, so the fiber faces are pressed together when connected. If you need any assistance in finding the right compression seal and fiber optic fittings for your needs, contact our team of experts at Electro-Meters today.

Conax PG Series (PG, MIC, MPG) – Compression Seal Fitting

Conax Technologies Model PG Packing Glands provide pressure/vacuum sealing for tubes, probes, pipe, cable or any single element assembly (not electrically isolating), including thermocouples, RTDs, thermometers, thermistor probes, capillary tubes, tubewells, multi-pair cables and analyzer sample tubes. PG glands seal against gases and liquids and resist element movement under pressure.

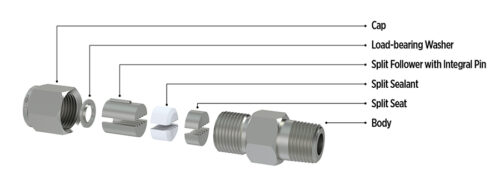

Conax PGS Series – Split Compression Seal Fitting

- Seals 1 Element

- For Gas or Liquid

- Stainless Steel Fitting

- Simple Assembly – Insert Element, Torque Cap

- Replaceable Sealant Permits Repeated Use Of Fitting

Conax SPG/DSPG Series – Multi-hole Split Compression Seal Fitting

- SPG Seals 1 To 11 Elements DSPG Seals Up to 17 Elements

- For Gas or Liquid

- Stainless Steel Fitting

- Soft Sealant

Conax SPGA/DSPGA Series – Multi-hole Split Compression Seal Fitting

Conax now offers split seal fittings with pressure ratings that are higher than typical ratings achieved with our legacy SPG and DSPG multi-hole split compression seal fittings

- Seals up to 12 Elements

- Multi-hole split seal fittings that carry both hydraulic and pneumatic catalog pressure ratings

- For liquid and gas

Conax HL Series – Hazardous Location Conduit Seal

- Stainless Steel Fitting

- For Gas or Liquid

- Easy Installation -No “Potting”

- Seals 1 to 12 Wires

- Pressure: Vacuum to 10,000 PSI (690 bar)

- Rated: 600 Volts to 55 Amps

Conax HD Series – High Density Feedthrough Assemblies

- Sheath Material: 300 Series SST, 4.5″ nominal length

- Temperature Range: -112°F to +250°F (-80°C to +120°C)

- Vacuum Rating: 5 x 10-6 mm HG @ 68°F (20°C)

- Leak Rate: 1 x 10-9 scc/sec He @ 68°F (20°C), 1 atm. applied

- Voltage Rating: 100 VDC

- Amperage Rating: 500mA

- Feedthrough Pressure Rating @ 68°F (20°C): 5000 psi (345 bar)

Conax MHC Series – Multi-hole Ceramic Compression Seal Fitting

- Seals 1 to 16 Elements

- For Gas or Liquid

- Stainless Steel Fitting

- Soft Sealant

Conax MHM Series – Multi-hole Metal Compression Seal Fitting

- Seals 1 to 16 Elements

- For Gas or Liquid

- Stainless Steel Fitting

- Soft Sealant

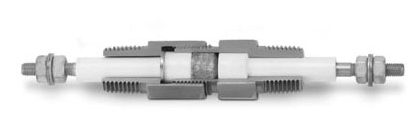

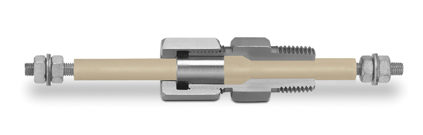

Conax TG/MTG Series – Instrumentation Wire Compression Seal Feedthrough

- Pressure/Vacuum Compression Seal

- Stainless Steel Reusable Fitting

- Soft Sealant

- Wires Easily Assembled or Replaced In Field

- Temperature Range From -300°F to +1600°F (-185°C to +870°C)

- Pressure: Vacuum to 10,000 PSI (690 bar)

- Seals 1 to 16 Elements

Conax EG Series – Power Compression Seal Feedthrough

- Seals 1 Electrode or Element

- For Gas or Non-Conductive Liquid

- Stainless Steel Reusable Fitting

- “Soft Sealant”

- Electrode Easily Assembled or Replaced in Field

Conax BSWS Series – Bearing Sensor Wire Compression Seal Feedthrough

- Stainless Steel Fitting

- For Bearing Oil Sealing

- Easy Installation – No “Potting”

- Seals 2 to 14 Wires

- Pressure: to 50 PSI (3.4 bar)

- Temperature Range: Ambient to 100°F (37.8°C)

- Field Adjustable

- Reusable Fitting

Conax TGM/MTGM Series – High Temperature Wire Compression Seal Feedthrough

TG assemblies with high-temperature fiberglass-insulated thermocouple wire are specially designed for applications where the sensor wire is exposed to process temperatures reaching up to 1400°F (760°C). This assembly is particularly targeted for use with vacuum and/or inert gas back-filled furnaces with vessel wall temperatures up to 200°F (93.3°C) and pressures not exceeding 300 psi.

Conax TGF/MTGF Series – High Temperature Wire Compression Seal Feedthrough

TG assemblies with fiberglass-insulated thermocouple wire are specially designed for applications where the sensor wire is exposed to process temperatures reaching up to 900°F (482°C). This assembly is particularly targeted for use with vacuum and/or inert gas back-filled furnaces with vessel wall temperatures up to 200°F (93.3°C) and pressures not exceeding 300 psi.

Conax TG-24/MTG-24 Series – Instrumentation Wire Compression Seal Feedthrough

This assembly consists of a Conax Technologies manufactured TG Feedthrough provided with a sealant and 24 AWG solid insulated thermocouple grade wires or copper wires. The feedthrough is furnished with 24″ of wire on each side. Longer wire lengths can be furnished as required.

Conax EGT Series – Power Compression Seal Feedthrough

- Electrode Teflon Sealing Gland

- Seals 1 Electrode or Element

- For Gas or Non-Conductive Liquid

- Stainless Steel Reusable Fitting

Conax FCA Series – Fiber Cable Assembly

- Transmission Loss: Less than 0.3db typical (not including connectors).

- Temperature Rating: -4°F to +185°F (-20°C to +85°C). Higher temperature models are available in some configurations. Please consult factory.

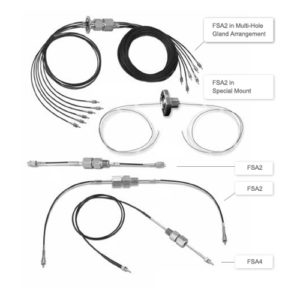

Conax FSA Series – Fiber Optic Feedthrough

- Helium Leak Rate: 1 x 10-6 scc/sec typical

- Transmission Loss: Less than 0.3db typical (not including connectors)

- Pressure Rating: 1000 PSIg (70 bar) standard, up to 3000 (207 bar) PSIg optional

- Temperature Rating: -4°F to +185°F (-20°C to +85°C). Higher temperature models are available in some configurations. Please consult factory.

Conax HEGPK Series – Power Compressions Seal Feedthrough

- Seals one electrode, conductor or element

- Temperature Range: Vacuum to 7,700 PSIg (531 bar)

- Voltage 8000 VDC

- Amperage to 200 amps

- Supplied with or without conductor

Conax HPEG Series – Power Compression Seal Feedthrough

- Each unit has a stepped electrode. Larger diameter of electrode is on the body side.

- Electrode is copper (CU), stainless steel (SS) and nickel (NI)

- Voltage rating 2000VDC

- Body material is 316SS, ASTM 479

- SST nuts and washers for NI and SS, brass for CU

- All prices include a pressure test at 68°F